Overview of the Biomass Industry in Malaysia

The Biomass Sector has been replaced by the 12th Malaysia Plan (12MP) as one of the eight strategic and high impact industries to regenerate economic growth.1 Malaysia is developing the potential of biomass industries in various sectors, including plantation, forestry, agriculture, livestock and fisheries industries. These sectors have been outlined as the focal areas of the National Biomass Action Plan 2023 – 2030. The Plan is mandated by the Ministry of Economy and spearheaded by the Ministry of Plantation and Commodities (KPK). The focal development of biomass industries in these five sectors has the potential to contribute to sustainable consumption and production, supporting Malaysia’s transition towards a low-carbon and circular economy with the creation of new jobs. The following is a brief introduction to the biomass industries in these five sectors:

- Plantation Biomass: Malaysia is known for its vast plantations, particularly oil palm and rubber. Biomass generated from these plantations can be utilised as various value add products. The plantation sector offers abundant biomass resources that can be harnessed for bioenergy generation and bio-materials production. The plantation biomass sector provides huge circular economy opportunities.

- Forestry Biomass: Malaysia possesses rich forest resources and the forestry sector offers significant potential for biomass utilisation. Timber industry residues can be utilised for bioenergy production including heat and electricity generation. Wood waste can also be transformed into value-added products like wood pellets, medium density fibreboard (MDF) etc. The sustainable management of forestry resources ensures responsible biomass extraction and at the same time preserving forest ecosystems and biodiversity.

- Agricultural Biomass: Malaysia’s diverse agricultural sectors generate substantial amounts of byproducts and waste materials. Agricultural residues can be converted into biofuels, carbonised products or used for heat and power generation. Agricultural residues can also be processed into organic fertilisers or animal feed. The utilisation of agricultural by-products for biomass industries can help reduce waste, promote resource efficiency and create additional revenue streams for farmers.

- Livestock Industry Waste: Malaysia has a thriving livestock industry. Livestock wastes, such as poultry manure, swine slurry and biogas from anaerobic digestion can be utilised as sources of renewable energy. The utilisation of livestock wastes for energy generation not only reduces greenhouse gas emissions but also offers an opportunity for waste management in livestock farming.

- Fisheries Industry Waste: Malaysia’s coastal and marine resources support a vibrant fisheries industry. Fisheries by-products can be processed into fishmeal, fish oil or hydrolysed for the production of bioactive compounds and liquid biofertiliser. Utilising fisheries by-products can reduce waste in the fishing industry and create additional economic opportunities.

Out of all these five sectors, oil palm biomass remains Malaysia’s primary biomass resource. The country has an estimated total of 5.67 million hectares of oil palm plantations, producing more than 90 million tonnes of dried palm biomass.2 Oil palm biomass is derived from a variety of oil palm byproducts, such as oil palm fronds (OPF) and oil palm trunks (OPT) from plantation operations. While empty fruit bunches (EFBs), palm kernel shells (PKS), mesocarp-fibre (MF) and palm oil mill effluent (POME) are generated from the milling operations. The oil palm biomass industry has been growing at a steady pace over the past few years, thanks to the interest and transition towards using lowcarbon renewable energy. Based on the data of 2019 compiled by the Energy Commission, Malaysia has achieved a total installed capacity of 440.5 MW powered by biomass including 70.65 MW coming from grid-connected power plant which is equivalent to 1.2% share of total electricity generated in Malaysia with a total emission reduction achieved i.e. 395.22 Gg CO2 eq.3 Hence, bioenergy can be used to decarbonise our electricity supply through dedicated action plan.

The Malaysia Government has acknowledged the significant contribution of biomass resources towards achieving our nation’s Sustainable Development Goals (SDGs). This acknowledgement comes in the form of various incentives and supports provided by key government agencies such as the Malaysian Investment Development Authority (MIDA), Malaysia Palm Oil Board (MPOB), Sustainable Energy Development Authority (SEDA), Bioeconomy Corporation, Malaysian Green Technology & Climate Change Corporation (MGTC) etc.

The biomass industry in Malaysia has shown tremendous growth potential in the last decade or so. We are now producing and exporting solid biofuels such as palm kernel shells and wood pellets to key markets of Japan and the Republic of Korea. The biofertiliser sub-sector has also been growing to meet the demand for sustainable farming using EFBs, POME, chicken dung, fish waste, woody biomass etc.

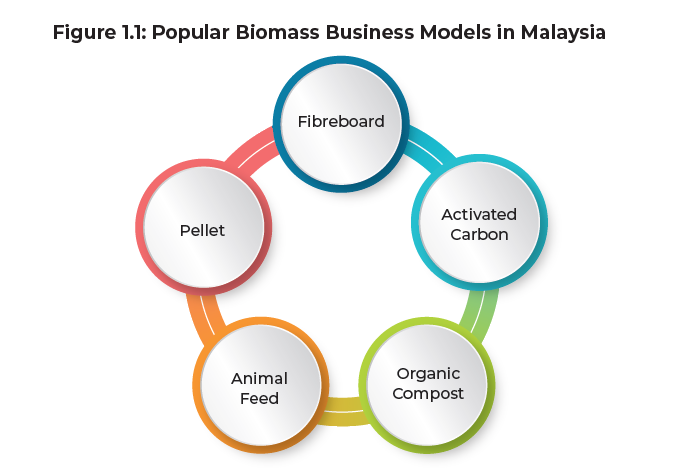

More focused efforts are needed to ensure that the economic harnessing of our biomass resources is aligned with the concept of Circular Economy. Such efforts include close engagement and coordination between government and industry, development of effective policy and action plans, collaboration between industry and academia, facilitation to access biomass feedstock and financing etc. According to MIDA website, the most popular bio-based products manufactured in Malaysia are as follows:

YAB Timbalan Perdana Menteri merangkap Menteri Perladangan dan Komoditi, YAB Dato’ Sri Haji Fadillah bin Haji Yusof telah melancarkan Pelan Tindakan Biojisim Negara 2023-2030 (PTBN2030) pada 7 Disember 2023 (Khamis) di Hotel Everly, Putrajaya pada 7 Disember 2023 semasa Persidangan Biojisim Kebangsaan 2023 kali ke-6.

PTBN2030 dibangunkan berdasarkan dokumen Rancangan Malaysia Kedua Belas (RMKe-12), Dasar Agrikomoditi Negara 2021-2030 (DAKN2030) dan dasar-dasar berkaitan bagi memperkasa industri biojisim dalam negara. Pelan tindakan ini turut mendukung tiga daripada enam tonggak dasar MALAYSIA MADANI iaitu Kemampanan, Kesejahteraan dan Ihsan yang dilihat sinonim dengan konteks alam sekitar.

PTBN2030 ini akan melibatkan seluruh ekosistem yang dinamik, bermula daripada perancangan, kawalselia, penilaian semula sektor biojisim, dan juga pembekalan serta permintaan pasaran. Fokus Kementerian Perladangan dan Komoditi (KPK) adalah terhadap sumber biojisim yang banyak terdapat di lima (5) sektor iaitu, perladangan, perhutanan, pertanian, penternakan dan perikanan. Potensi biojisim daripada sektorsektor ini dianggarkan berjumlah 182 juta tan metrik setahun yang mana hampir 90% diperolehi daripada industri biojisim perladangan.

PTBN2030 juga selari dengan Pelan Hala Tuju Peralihan Tenaga Negara (NETR) dalam menyasarkan pelaksanaan projek co-firing di stesen janakuasa elektrik melalui pembakaran bahan api campuran antara arang batu dengan pelet biojisim. Ini juga bertepatan dengan sasaran tenaga lestari ke arah 70% power generation energy mix menjelang 2050 yang akan menjadi game changer dalam sektor tenaga negara.

Penubuhan Hab Biojisim disasarkan bagi melaksanakan proses pengumpulan bahan mentah biojisim secara berpusat dan teratur. Hab Biojisim ini akan dapat memainkan peranan yang berkesan dalam menggerakkan rantaian bekalan biojisim negara secara sistematik dan efisien.

Kementerian yakin PTBN2030 ini mampu menarik pelbagai pihak berkepentingan khususnya pekebun kecil, perusahaan kecil dan sederhana, pembiaya, penyedia perkhidmatan teknologi dan perkhidmatan logistik, dan pelbagai perkhidmatan sampingan untuk terlibat dalam sektor ini. Justeru, pihak Kementerian akan meneruskan pelbagai usaha dalam meningkatkan pembangunan industri Agrikomoditi Negara yang merangkumi sektor biojisim ke arah pembangunan mampan demi kemakmuran ekonomi negara.

OIL PALM BIOMASS AT THE PLANTATIONS

Quick Fact

The oil palm trunk (OPT) refers to the main stem of the oil palm tree which becomes available when the tree is felled during the replanting process.

The oil palm trunk (OPT) refers to the main stem of the oil palm tree which becomes available when the tree is felled during the replanting process.

Oil palm fronds (OPF) are obtained from theuppermost part of the oil palm tree, specifically theleaves or fronds which are available during annualpruning activity and replanting process.

Findings: Utilisation of Oil Palm Biomass Generated from Plantation

| Current Utilisation | Potential Utilisation | |

| Oil Palm Trunk (OPT) | OPT plywood, blockboard, OPT straw, palm wood and OPT pellets used as green fuel or for furniture boards |

Used as sap, engineered lumber, bio-composite, biosugar (C5 & C6), bioalcohols, bioplastics |

| Oil Palm Fronds (OPF) | Mulching as organic fertiliser and small scale animal feed9. Recent innovation includes oil palm leaf tea products and OPF pellets. |

Biocomposite, phytonutrients extraction, biosugars, bioalcohols, used as green fuel for biomass boilers |

OIL PALM BIOMASS AT THE PALM OIL MILLS

Quick Fact

Empty Fruit Bunch is the fibrous material that remains after the extraction of palm oil from the fresh fruit bunches.

Mesocarp Fibre is the fleshy middle layer of the oil palm fruit.

Palm Kernel Shell is a by-product of the palm oil extraction process.

Palm Oil Mill Effluent (POME) is produced during the processing of fresh fruit bunches in palm oil mills.

Palm Kernel Cake (PKC) is a by-product obtained after the pressing of kernel oil fromthe kernel flesh of the palm fruits; PKC is generated from kernel crushing plants.

Findings: Utilisation Oil Palm Biomass Generated from Milling Operation

| Current Utilisation | Potential Utilisation | |

| Empty Fruit Bunch (EFB) | Used for mulching, compost, biochar, biofertiliser, residue oil extraction, EFB pellets/briquettes, torrefied fuel pellets, long/short fibres for mattress making, erosion control products, carboxyl methyl cellulose (CMC), bio-based packaging products, nanocellulose, EFB pulp & paper. |

Used for biocatalyst, bioresin for bioplastics,Used for biocatalyst, bioresin for bioplastics,biosugar (C5, C6) , bioalcohols, activatedcarbon, bioethanol and microcrystallinecellulose. |

| Palm Kernel Shell (PKS) | Used as green fuel for boiler, biochar, wood vinegar, activated carbon, fuel pellets. |

Used for production of graphite and graphene. |

| Mesocarp Fibre (MF) | Residue red palm oil extraction, green fuel for boiler. |

|

| Palm Oil Mill Effluent (POME) | Used as biofertiliser solutions, methane capture for biogas and bioCNG for injection into natural gas pipeline. |

Used for microalgae cultivation, commercialised scale bioCNG, bioCNG as transportation fuel |

Quick Fact

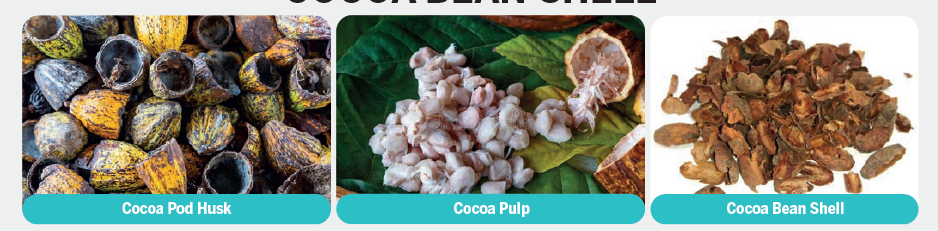

The cocoa husk is the tough outer layer of the cocoa pod, providing protection to the pulp and beans.

The cocoa pulp is the sweet and edible material that surrounds the cocoa beans within the cocoa pod.

The cocoa bean shell is the thin, brittle covering of the cocoa bean itself, which is removed during processing.

Findings: Utilisation of Cocoa Biomass

| Current Utilisation | Potential Utilisation | |

| Cocoa Pod Husk & Pulp | Cocoa pod husk and pulp are decomposed naturally as fertiliser after harvesting. |

Used for biochar, activated carbon, bioorganic fertiliser and soil enrichment media. |

| Cocoa Bean Shell | Cocoa bean shells are used as green fuel in biomass boilers which have proven their energy efficiency solution. |

Used for livestock feed, other potential applications include biohydrogen, bio-oil, liquid smoke, bioethanol, biogas etc. |

Quick Fact

Sago biomass is generated through two distinct activities. Firstly, during the harvesting of sago logs at the plantation, fronds are produced. Secondly, at the sago mill processing centres, waste materials such as barks, hampas and sago mill effluent are generated during the starch extraction process.

Findings: Utilisation of Sago Biomass

| Current Utilisation | Potential Utilisation | |

| Frond | Sago fronds are commonly laid on the ground in sago farms to facilitate walking, rolling harvested logs and preventing weed growth. |

Silage made from fermented sago fronds |

| Barks | Barks are usually discarded | Barks can be utilised as green fuel but the usage remains limited due to its acidic properties. |

| Hampas |

Sago hampas can be utilised to create animal feed or compost for |

Hampas can be utilised to produce animal feed |

| Waste Water | Wastewater is usually discarded | . |

Quick Fact

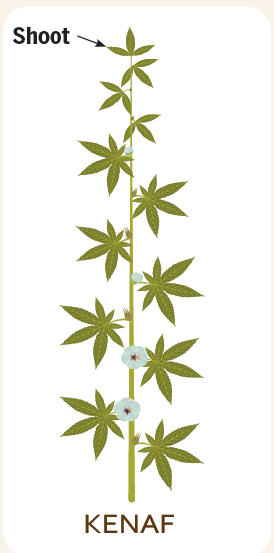

Kenaf is cultivated primarily for its fibre. During the cultivation process, tender and young stems known as kenaf shoots are produced. These shoots, located near the upper part of the stem, are harvested separately from the stalks and currently used as animal feed.

Current Utilisation of Kenaf Shoot

The kenaf industry in Malaysia is primarily driven by smallholders. Currently, kenaf shoots are utilised as animal feed. The nutritional composition of kenaf shoot makes it a source of valuable feed for livestock, providing essential nutrients and promoting healthy growth.

Quick Fact

Pepper is a woody climber that requires support to grow upward. The possible types of biomass are:

1) Trimmings from live trees, including leaves and small top branches, which are used to support the growth of pepper.

2) Grass cleared from the surrounding area of the pepper trees.

3) Trimmings from shoots and side branches of the pepper trees, which are pruned quarterly or annually.

4) Replanting activities of pepper trees, where old pepper trees become available for biomass utilisation.

Findings on Pepper Biomass Utilisation

Presently, the biomass generated at the pepper planting site is left unused and allowed to decompose naturally. A well-maintained pepper plant typically remains productive for 15 to 20 years or even longer. During the replanting process, the old pepper trees are left at the site to decompose naturally. It is possible to plant up to 2000 pepper

plants per hectare, with harvest usually taking place around the third year of growth. In new plantings, flowers are trimmed to promote healthy plant development, and the discarded flowers are left at the site. In terms of production distribution, Sarawak accounts for 98% of the pepper production

For more enquiries, please contact:

Setiausaha Bahagian

Bahagian Biojisim dan Biobahan Api (BBA)

Ministry of Plantation and Commodities

No. 15, Level 5-13,

Persiaran Perdana,

Precint 2,

62654 Putrajaya, MALAYSIA

Emel : bba [@] kpk.gov.my